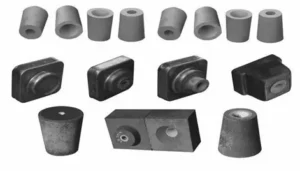

| Zirconia Metering (Sized) Nozzle | Outer Composite Tundish Nozzle | |||

| Chemical Analysis | A Quality | B Quality | Alumina | Magnesia |

| ZrO2 (%) min | 96 | 95 | – | – |

| MgO (%) | 2.4 – 3.3 | 2.4 – 3.3 | – | 96 |

| Al2O3 (%) | 0.02 | 0.4 | 97 | – |

| Fe2O3 (%) max | 0.02 | 0.04 | 0.1 | 0.7 |

| Si2O3 (%) max | 0.3 | 0.6 | 0.2 | 0.8 |

| A.P. (%) | 2 – 4 | 5 – 7 | ||

| C.C.S. Mpa (%) min | 130 | 130 | ||

| B.D. (g/cm3) min | 5 – 4 | 5 – 2 | ||

| Refractor () min | 1900 | 1900 | ||